Catheters owe their efficiency to the choice of materials and design used. The inner and outer layers, along with the strategic choice of a middle layer—be it coiling or braiding—allows for optimal catheter performance. In this article, we discuss the differences between coiling and braiding and their outcomes on the final product.

While each layer serves a distinct purpose, the art of catheter engineering lies in the ability to tweak all three layers for optimal performance tailored to user requirements.

The inner layer of a catheter is typically PTFE liner, providing a lubricious Inner Diameter (ID) with great flexibility. Stiff ploymers can be used in the ID as an alternative, at the expense of flexibility, providing the result of increased stiffness.

The outer layer, composed of polymer extrusions, acts as a primary determinant of the catheter’s overall flexibility.

It is in the middle layer where we delve into the complexities of coiling vs braiding. Both processes serve a unique purpose, providing different outcomes to the overall function and output.

Braiding, a common reinforcement technique, introduces a numbers of customisation options, based on the needs of the user. The choice of wire sizes—both flat and round—offers versatility. PPI (Picks per inch) or wires crossing can be varied over the length of the catheter, depending on what the performance requirements are. High PPI gives greater flexibility and low PPI results in increased rigidity and torque transmission.

Pros:

- Better torque transmission

- Reduced radial expansion

- Good pushability and column strength

Cons:

- Less kink resistance

- Potential ovalization in the ID in tight bend radii

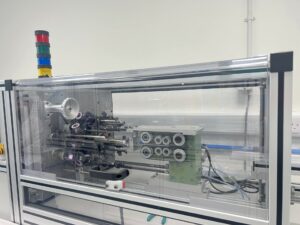

– Braider at ICS Medical Deivces

Coiling is another reinforcement method which brings its own set of considerations. Various wire sizes—round and flat—provide flexibility for different catheter sizes. Larger wires e.g. 0.006” x 0.018” stainless steel wire could be used for a large ID catheter, such as structural heart. Small round wires 0.0015” OD is more suitable for high flexibility in small, neuro catheters. The pitch can be adjusted depending on the flexibility required.

Pros:

- Greater flexibility, increased kink resistance

- Maintains a round ID in tight bend radii

Cons:

- Poor torque

- Susceptible to stretching or compression in tension or compression

– Coiler at ICS Medical Deivces

For catheters needing a blend of characteristics, a hybrid approach offers a strategic solution. If wall thickness allows, combining both braid and coil can be particularly useful. This hybridisation caters to large diameter catheters requiring a small bend radius and angle. The proximal end, needing less flexibility, may feature a low PPI braid with a stiff extrusion. Meanwhile, the flexible distal end benefits from a coil and braid combination for better flexibility and kink resistance.

ICS Medical Devices are your flexible partners in the design, develpoment and manufacturing of catheters and delivery systems. To speak with our management and engineering team about your project, send us an email at info@icsmedical.com